01.

Clinker, gypsum and admixture – the three components are mixed in a certain specific proportion and transported on the belt conveyor to the cement mill for further grinding.

02.

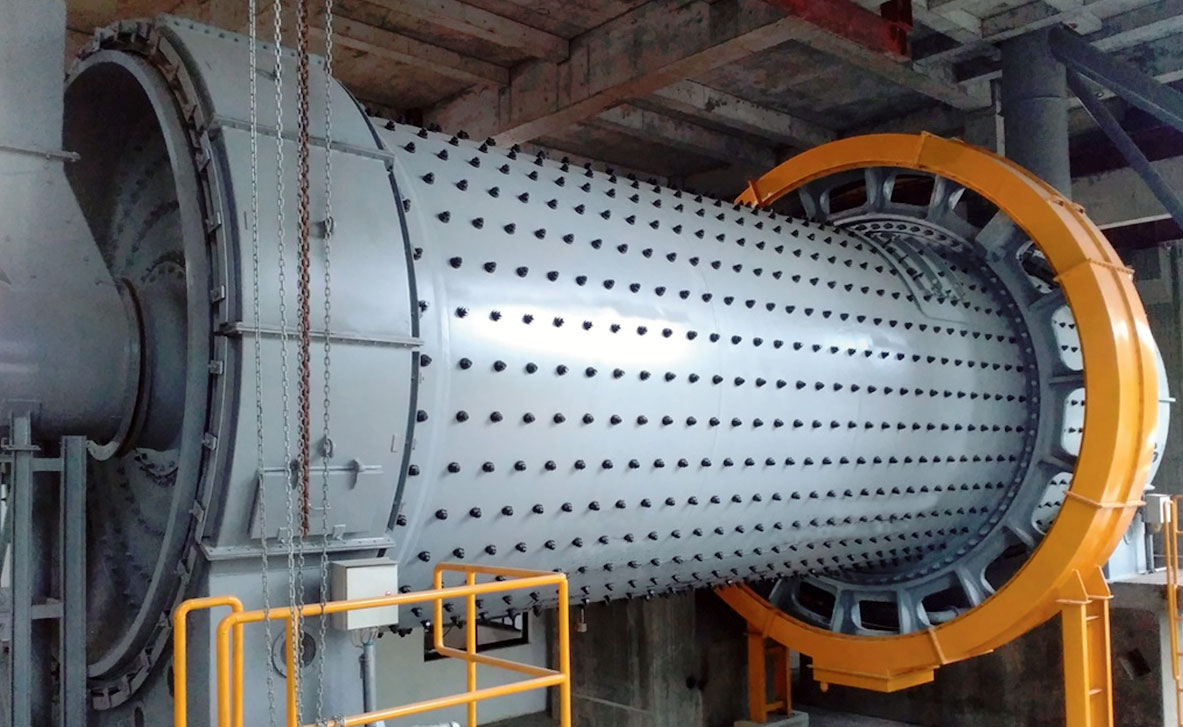

Cement roller press, cement ball mill, cement vertical mill is where the mix is further ground.

03.

The cement mill grinds all materials into specific sizes and the particles are screened.